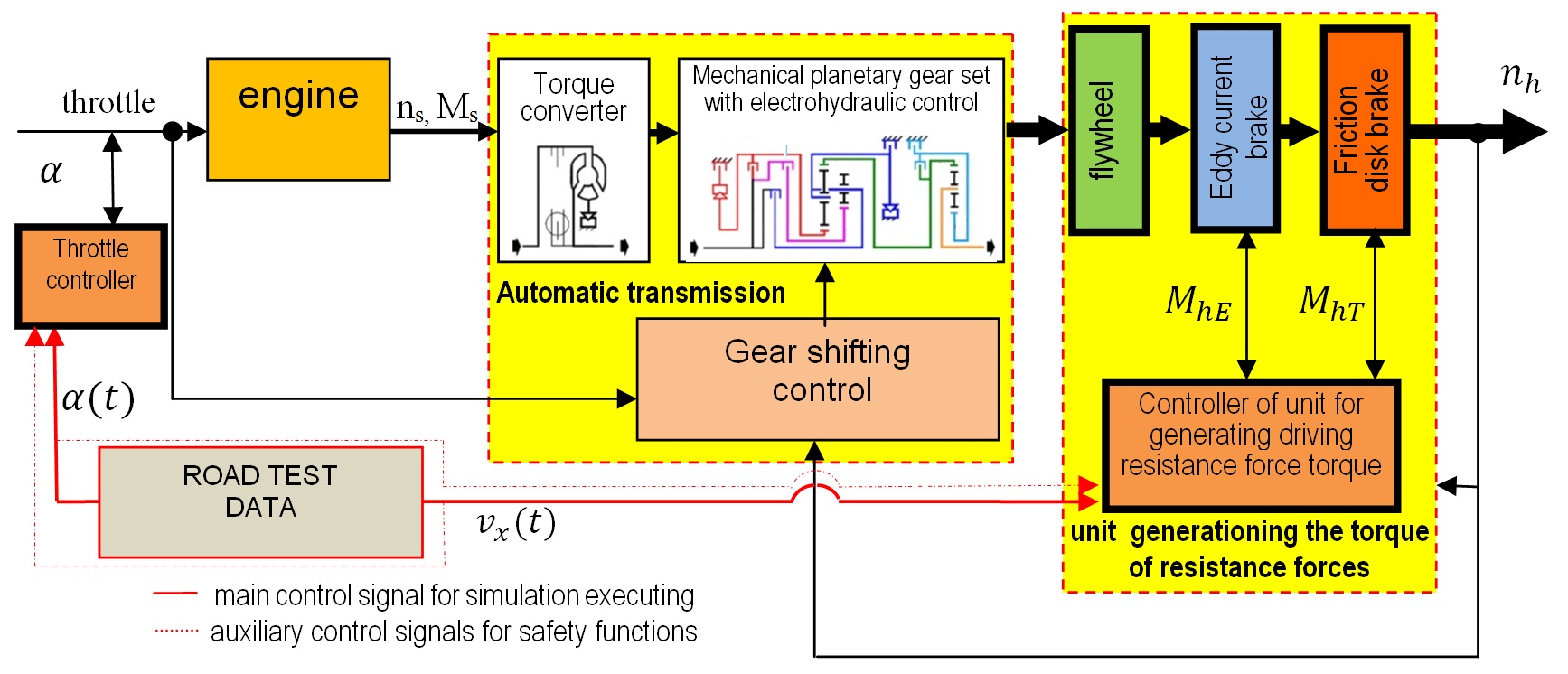

Together with Janusz Walkowiak (Ph.D. Eng.) it was built a test bench equipped with an engine, automatic transmission and specially designed brake torque generation subsystem to simulate dynamically changing road drag torque.

This subsystem and engine throttle are controlled by a specially designed prototype controller allowing to reproduce vehicle velocity time history on the base of signals of the throttle angle and vehicle velocity acquired during road tests. This controller is an integral part of the test bench and due to its functionality enables to make testing possibilities wider offering also possibility to make highly repeatable tests of dynamically changing drive train loads and controls. Significantly better signal measuring possibilities compared with road tests allow to get much more information about drive train working conditions.

Fig. Control scheme of prototype control software of test bench

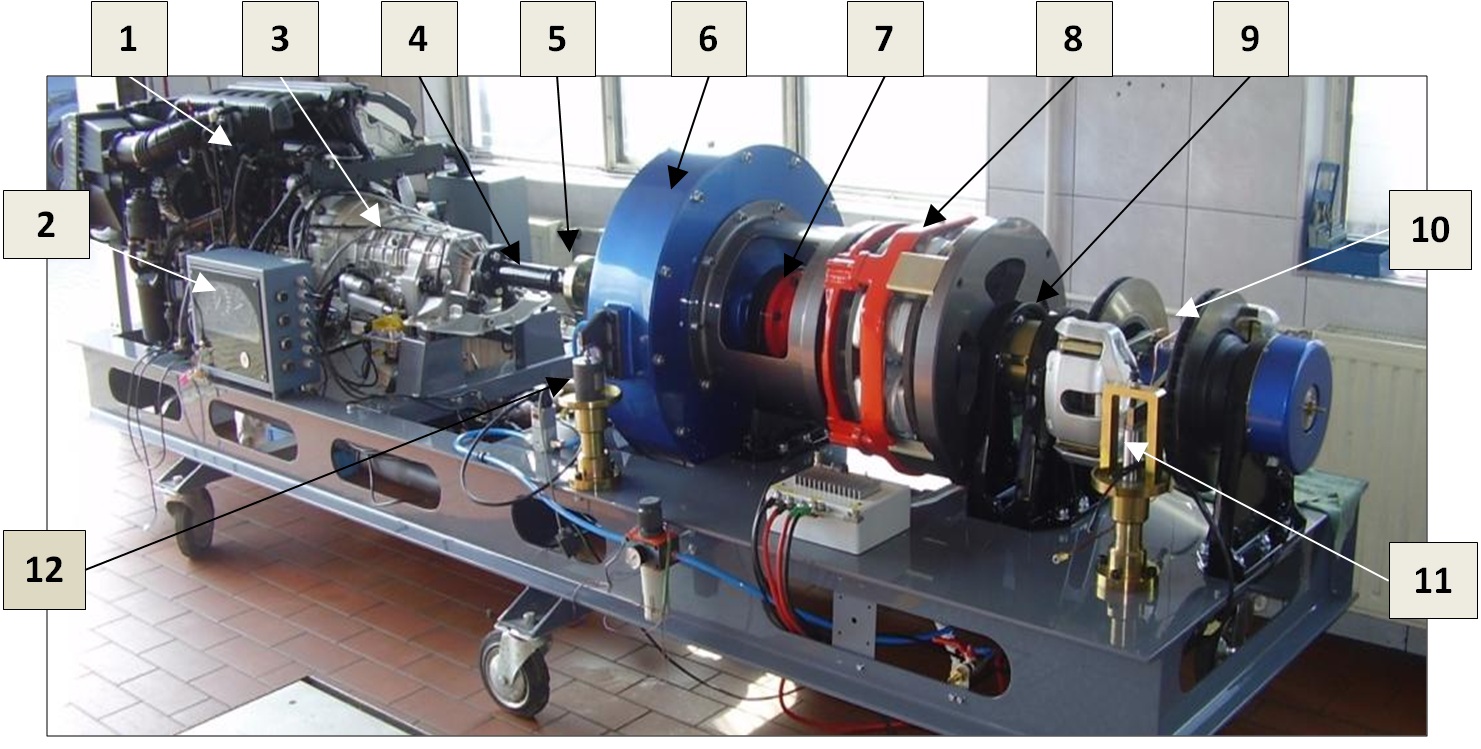

Fig. View of build test bench of drive-train: 1-engine, 2-control unit (instrument panel), 3- automatic transmission, 4-driveline shaft, 5- driveline shaft torque sensor, 6 - flywheel with cover, 7-reduction planetary gearset, 8 – Eddy current brake, 9 – safety clutch, 10-unit of friction brakes, 11-friction brake torque sensor, 12-Eddy current brake torque sensor.

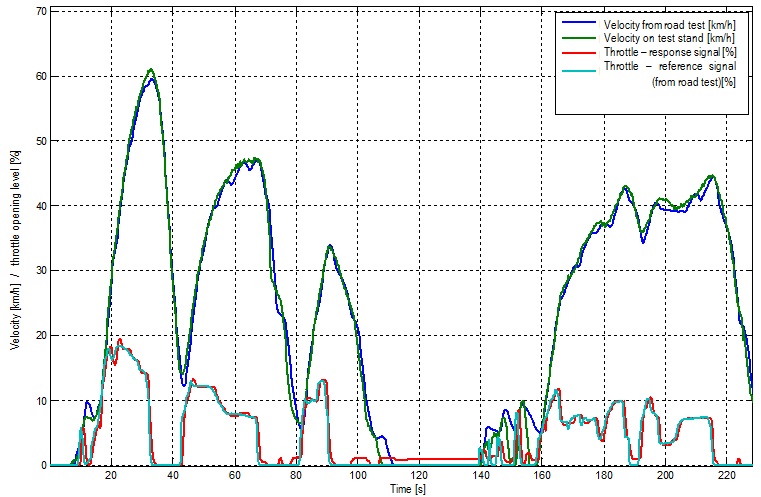

Fig. Test bench reproducing simulation results